Frame Prefab with Manpower

The Assembly Table from woodtec

Industry 4.0 is not necessarily synonymous with automation and automation has nothing to do with profitability. For the Swiss supplier and machine manufacturer woodtec Fankhauser GmbH, the carpenter with his skills and knowledge should and will remain the focus of timber construction.

Wir Holzbauer, Spezialausgabe 2019

Automatic Google-Translation from the German Original:

The term “Industry 4.0” is on everyone’s lips and goes hand in hand with the idea that robots will do all the work for us in the future. You feel conservative and you almost have to have a guilty conscience if you haven’t ordered a processing portal for your element production. Because it cannot be otherwise than that robotization is innovative and the future of timber construction will be. Just like in the auto industry.

For Benjamin Fankhauser, sales manager at woodtec Fankhauser GmbH, this fad is highly dubious, both technically and economically. From a business point of view, the central question must always be return on investment. “When I hear feedback from plant managers who have not gotten faster with massive automation in production, I see the future of timber construction in a black light,” says Fankhauser. The calculation is very simple. How much time do I currently need for a work step and how much time do I need after investing in the machine, taking into account the amortization and maintenance costs? For this reason, woodtec companies recently started offering customers support in time recording and a time comparison with the industry average as a service. This gives them a picture of the status quo, potential for improvement can be better explored and investments can be better planned.

But even if you can justify a robot from an economic point of view, that does not automatically mean that it is technically the more sensible solution, says Fankhauser, despite his master’s degree in Robotics and Autonomous Systems at EPFL, or perhaps because of it. Even if fully automated systems are fascinating, you shouldn’t be blinded by them. «For a short time now, we have been welding series welded parts by hand again in our own factory, which were previously welded by robots. An investment in an inexpensive circular welding table enables our welders to be much more efficient than the robot, ”says Fankhauser, explaining the principle. An important area of robotics deals with the fact that humans can reach their full potential – it is not about replacing them. Think of Google Glasses or exoskeletons. In this sense, woodtec Fankhauser also sees the future change in timber construction. The skilled craftsman cannot be replaced by fully automated solutions. From a technical point of view, a robot makes sense where it takes on a complex task that humans cannot perform, or for repetitive tasks that the machine can perform many times faster. This is not the case per se in timber construction, at least not in the prefabrication of timber elements. The individual work steps (screwing beams together, cutting panels, etc.) are relatively simple, but not repetitive, as each element is always different. In industry, one speaks of batch size 1.

In addition, the work steps require a lot of flexibility, adaptability and experience, since the material wood has a different quality each time, so the starting point is slightly different each time. In such cases, humans are much better suited than machines. The productivity of the individual carpenter can also be significantly increased if he is provided with the right tools.

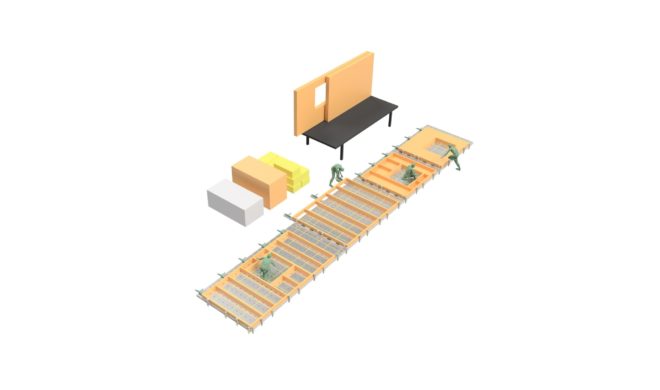

This is where woodtec’s decades of experience in timber construction come into play. Company founder and managing director Thomas Fankhauser, a trained carpenter with a later degree as a civil engineer, knows timber construction first hand and has followed prefabrication for years. “We are in active contact with dozens of timber construction companies, reviewing processes and optimizing individual work steps,” says Benjamin Fankhauser. It all started with the conception of a modular assembly table, which is now used by over 350 companies. For the assembly of the wooden frame and the initial planking, the production times could be reduced by 30 to 50 percent. Since then, based on this, accessories and devices have been continuously developed in order to make further work steps even more efficient, such as the planking of the elements, nailing off the planking or the production of roof elements. So far without having to replace the carpenter with a machine. And it should stay that way, because the possibilities for increasing production are far from being exhausted.

Elementbau mit Manpower

Der Montagetisch von woodtec

Efficient handling and team size 1

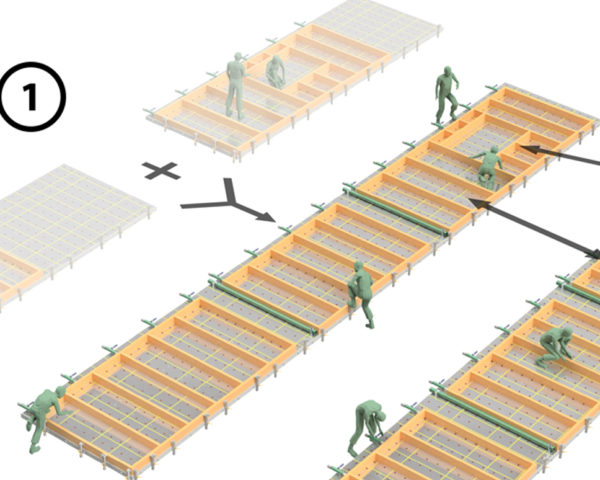

An important future development is to reduce the team size per workstation from two to one man, as has long been the case with carpenters. Studies have shown that two workers are only around 1.6 times as fast as one alone. If waiting times and additional cooperation effort resulting from teamwork can be eliminated, productivity can be increased by around 20 percent. The big obstacle is the laying on of long sleepers and the planking, which generally requires two pairs of hands. Since the use of hoists like vacuum lifters puts too much load on the main crane, it is seldom possible to get around the workers helping each other out. To make this as efficient as possible, the companies work with modular workstations. Instead of setting up an assembly table for each workstation, a long table is installed that is divided into workstations of different sizes depending on the length of the elements. This very organic layout not only optimizes the work surface and maximizes the use of the facility. It also enables the teams to be locally close together and to lose little time while helping out and switching to the other station.

Sooner or later, however, many companies expect woodtec to install a second crane level. “Our studies show that an average of 25 percent of the time is spent just moving the paneling from the stack of materials to the element,” explains Fankhauser. Existing solutions with stationary slewing cranes and tube lifters are still too slow and have too limited a work area. Since last year, woodtec has been working hard on a prototype for a gantry crane with which every craftsman can really produce his own element autonomously. The new device is to be presented for the first time at the Holz 2019 in Basel.

More News

Show All

Prefab: Focus on Material Handling

The new production plant of Stuberholz AG does not score with fully automatic…

Stationary Workplaces Work Best

The Lehner GmbH from Heidenheim relies on stationary workplaces in their newl…

Added Storeys and Extensions

With increasing urbanization and the legislative measures against urban spraw…

Frame Prefab with Manpower

Industry 4.0 is not necessarily synonymous with automation and automation has…

Prefabricate Roofs

A new trend could emerge in the manufacture of roof trusses.

Modular Prefab

The trend towards individual solutions in timber construction and constructio…

Glued Box Girders – Completely Without Screws

Glued box girders for roofs and ceilings with a larger span

Timber for Athletes

Whether sprinting, hurdling, long jump or javelin throwing – thanks to ribbed…

More Flexibility with Modular Workstations

The new concept for optimizing space, minimizing transport and material flow …