Your very own CLT Production

covering a variety of needs

Your Own Buidligns

For Builders whos want to produce their own CLT instead of relying on others:

- Short Lead Times

- Cost Reduction of 30-50%

- Custom-sized panels with cut-outs for doors and windows

Supplier

Market a wood product with hight added value?

- Any Panel Size is possible

- Low Investement Risk

- Grow Step by Step

Tech Firm

You want to manufacture exceptional productions like Magnumboard?

- High Flexibility

- Low Starting Investement

- Expand with Increasing Demand

Advantages of Vacuum

- Flexibility

- Quality

- Finance

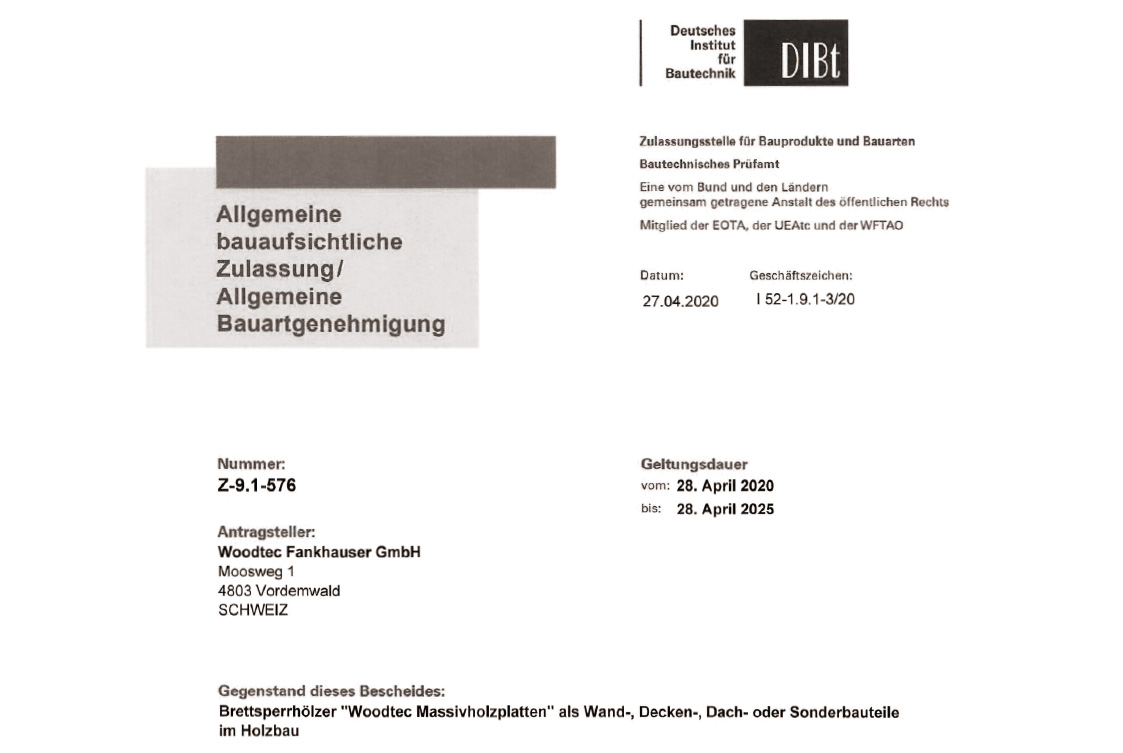

Certification

‘Woodtec Massivholz‘ has its own national technical approval (allgemeine bauaufsichtliche Zulassung Z-9.1-576) since 2005 from the German Institut für Bautechnik (DIBt), that boast widespread approval across borders.

Our clients thus produce certified panels under licence from day one. The dimensional range has been greatly extended as from April 29, 2020.

Extension Phases

- Starter Kit

- Phase 1

- Phase 2

- Phase 3

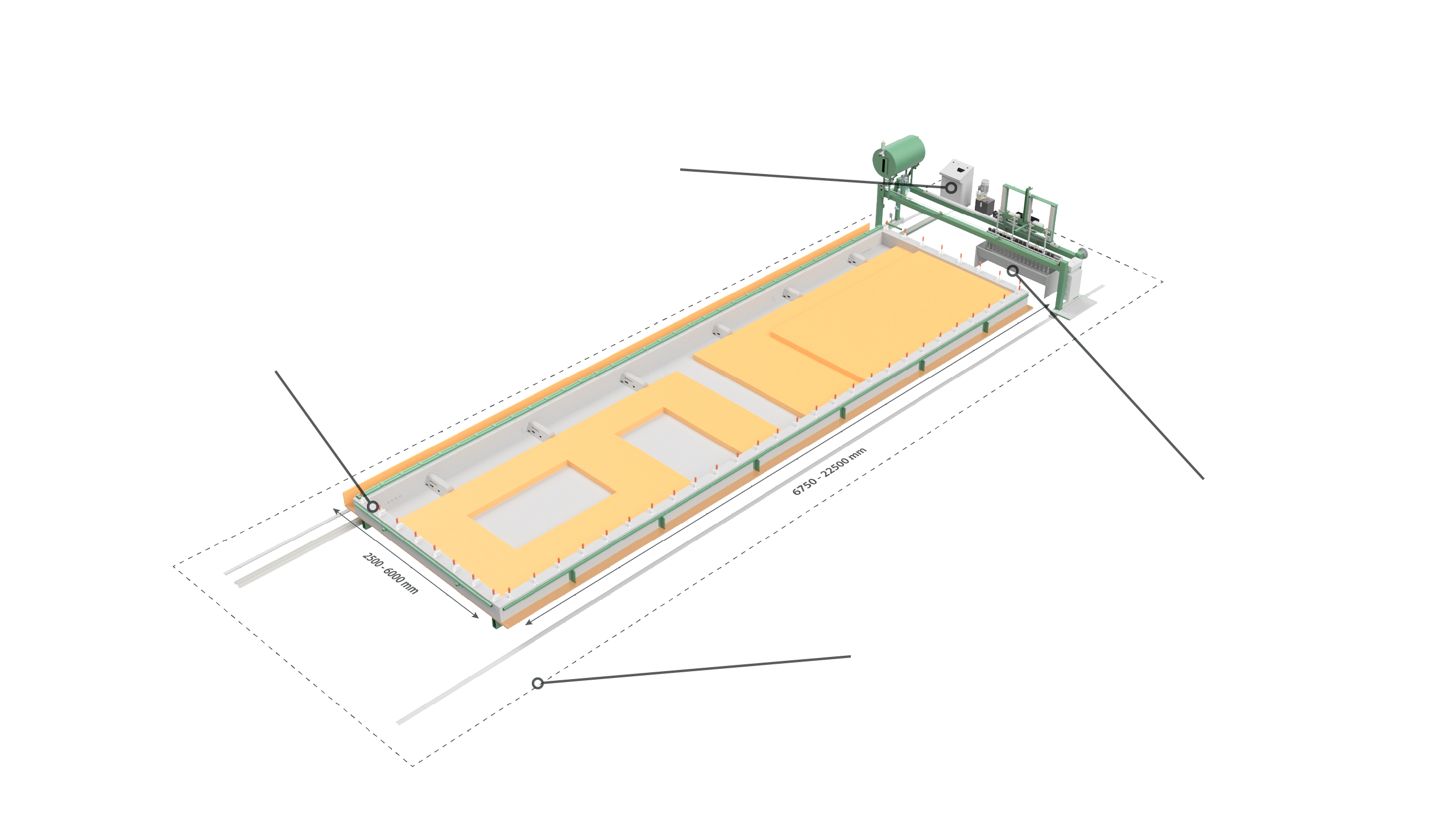

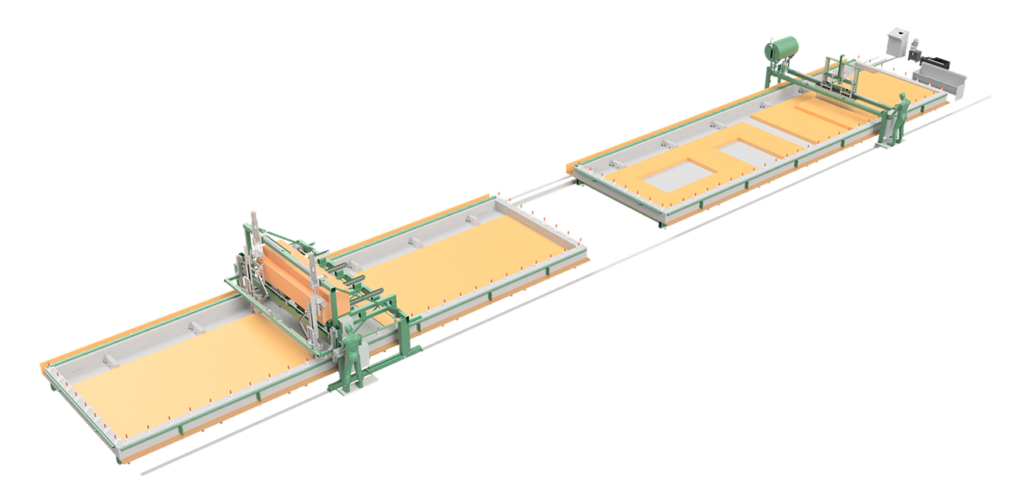

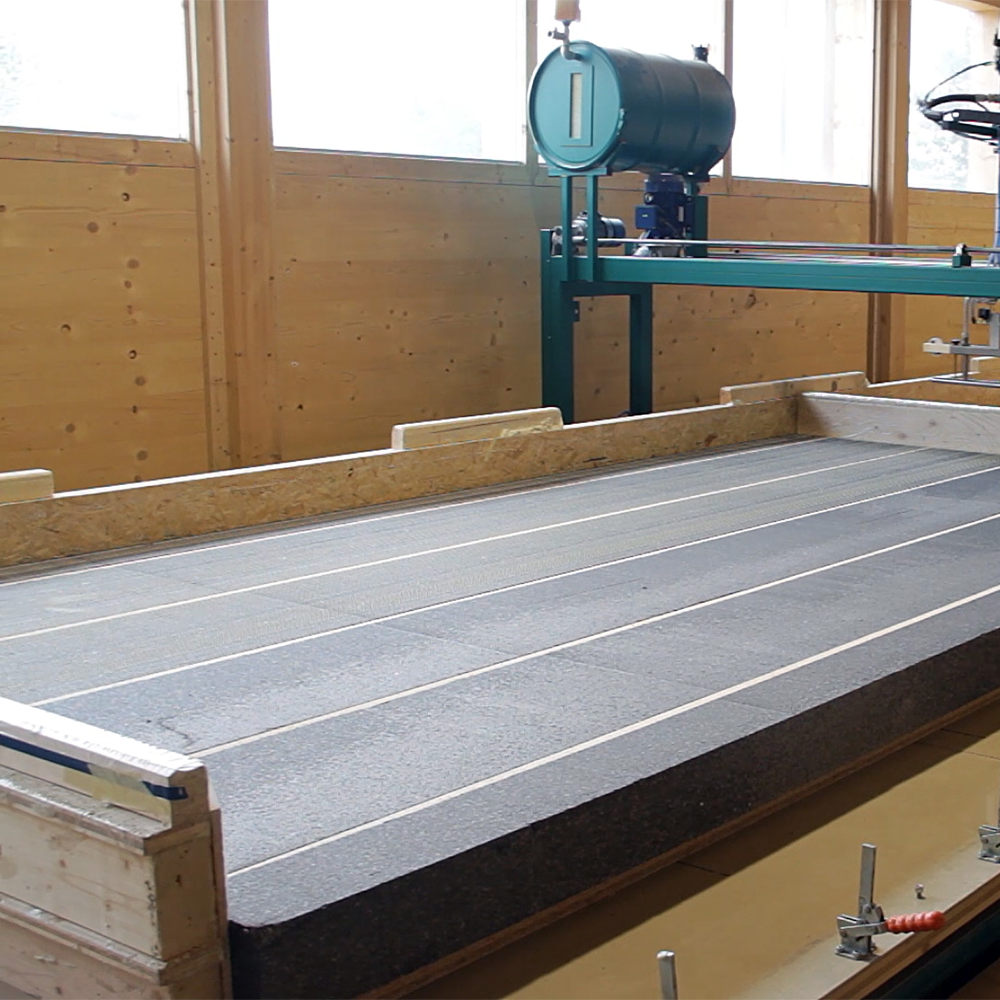

Vacuum Press

+ Adhesive Application Portal

Manual Feeding of the Press. Ideal for low risk market entry and development.

| Number of Operators | 3 |

| Adhesive Open Time: | 40 – 50 min |

| Number of Pressing Cycles: | 2 – 3 / Schicht |

| Output: | 2 – 3’000 m3 / year / shift |

* indications for a 3.5×15 m press at 30% of the theoretical output

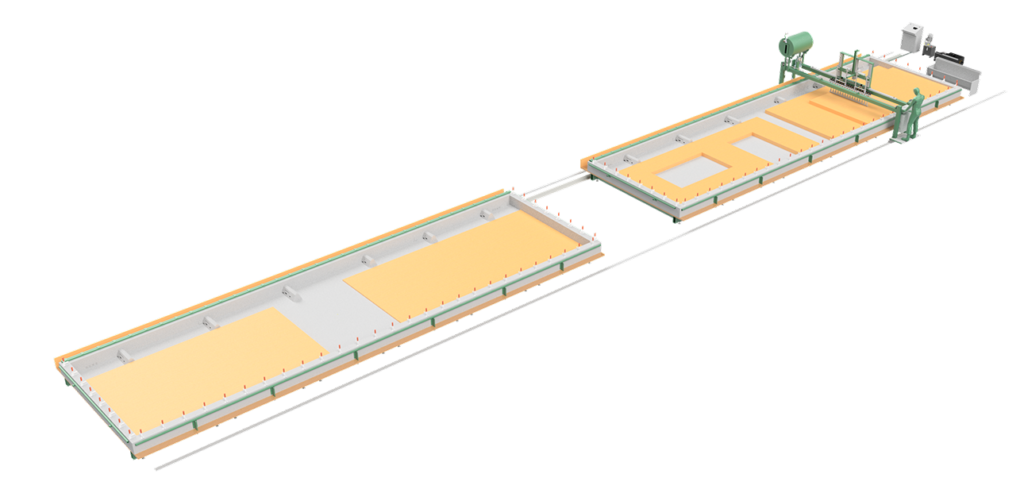

Additional Presses

While one press is under pressure the next one is being loaded. Cost-effective solution for multiply output and optimizing human ressources.

| Number of Operators: | 3 |

| Adhesive Open Time: | 40 – 50 min |

| Number of Pressing Cylces: | 2 – 3 / shift |

| Output 2 presses: | 4 – 6’000 m3 / year / shift |

| Output 3 presses: | 6 – 9’000 m3 / year / shift |

* indications for a 3.5×15 m press at 30% of the theoretical output

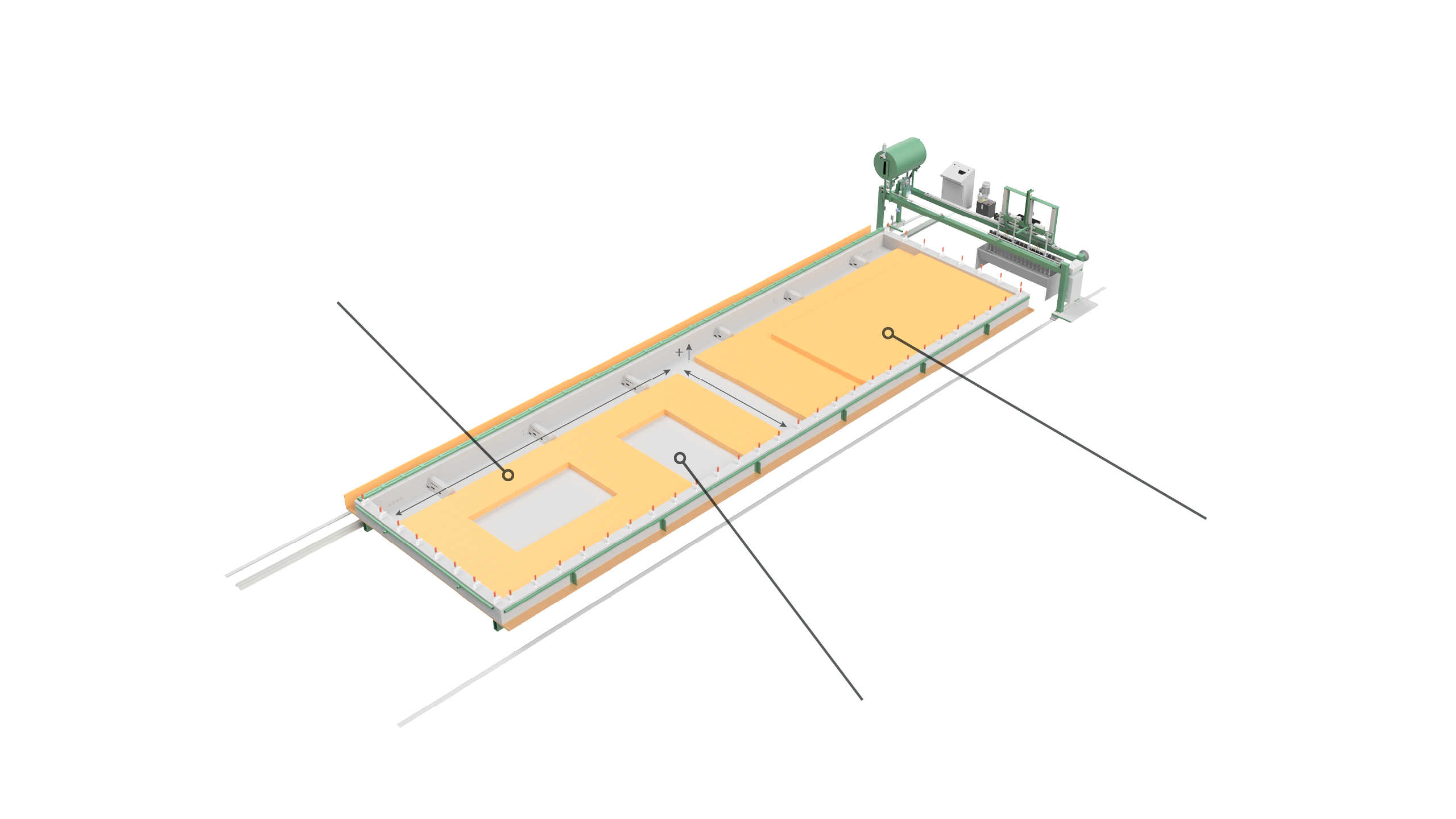

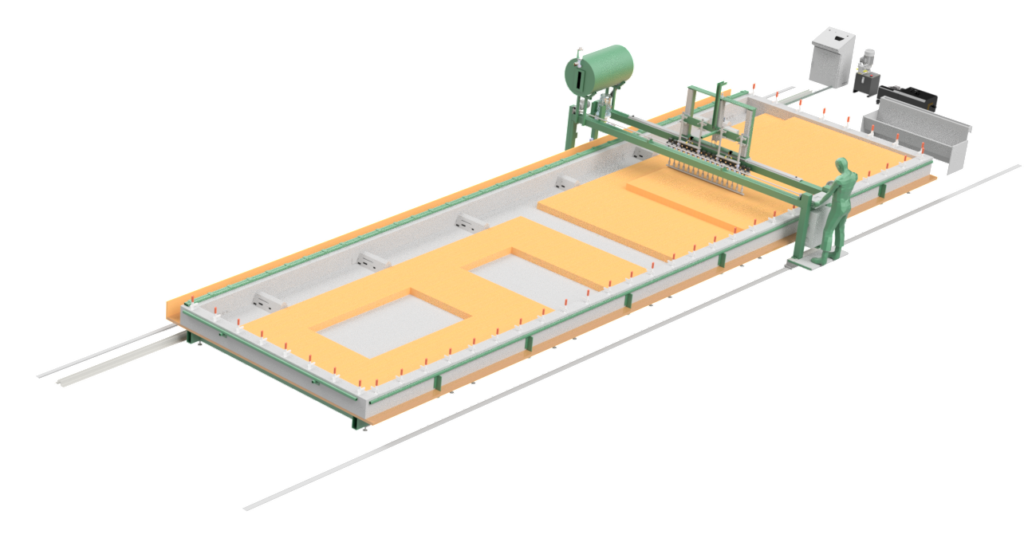

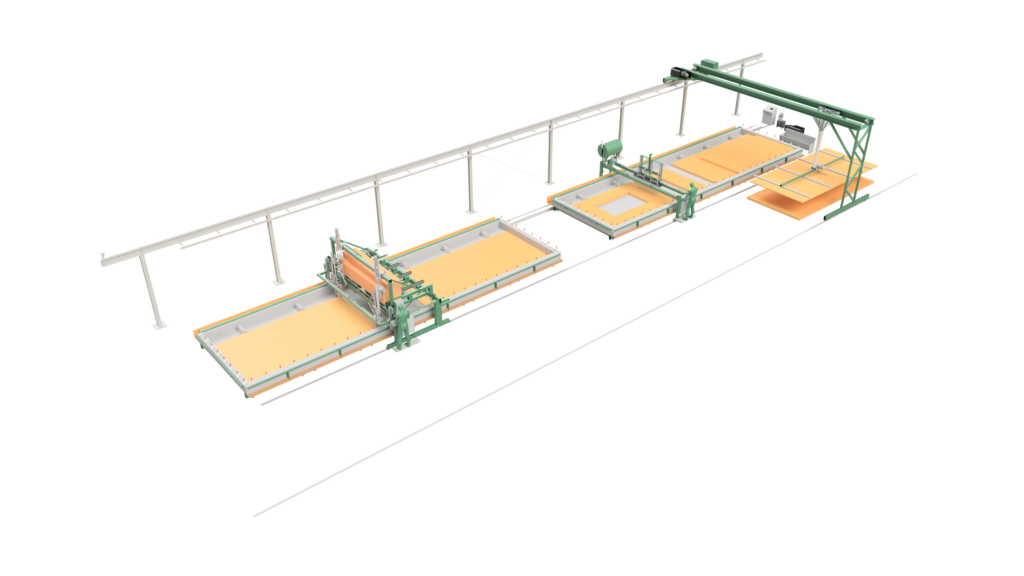

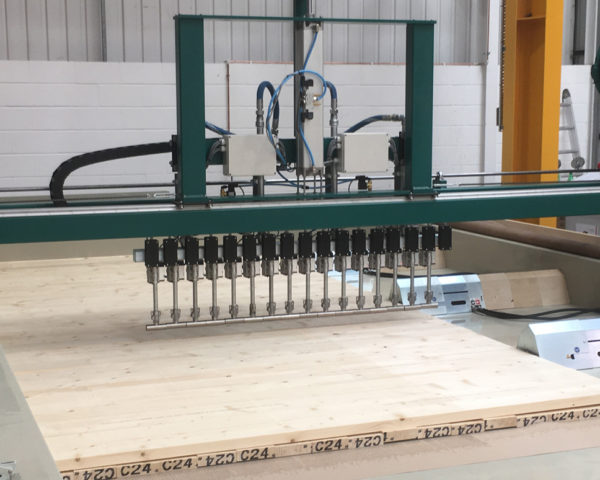

Lateral Lamella Conveyor Portal

Lateral Lamellas are being destacked and inserted in the press. More pressing cycles with fewer operators.

| Number of operators: | 2 |

| Adhesive Open Time: | 30 min |

| Number of Pressing Cycles: | 4 / shift |

| Output 2 presses: | 8’000 m3 / year / shift |

| Output 3 presses: | 12’000 m3 / year / shift |

* indications for a 3.5×15 m press at 30% of the theoretical output

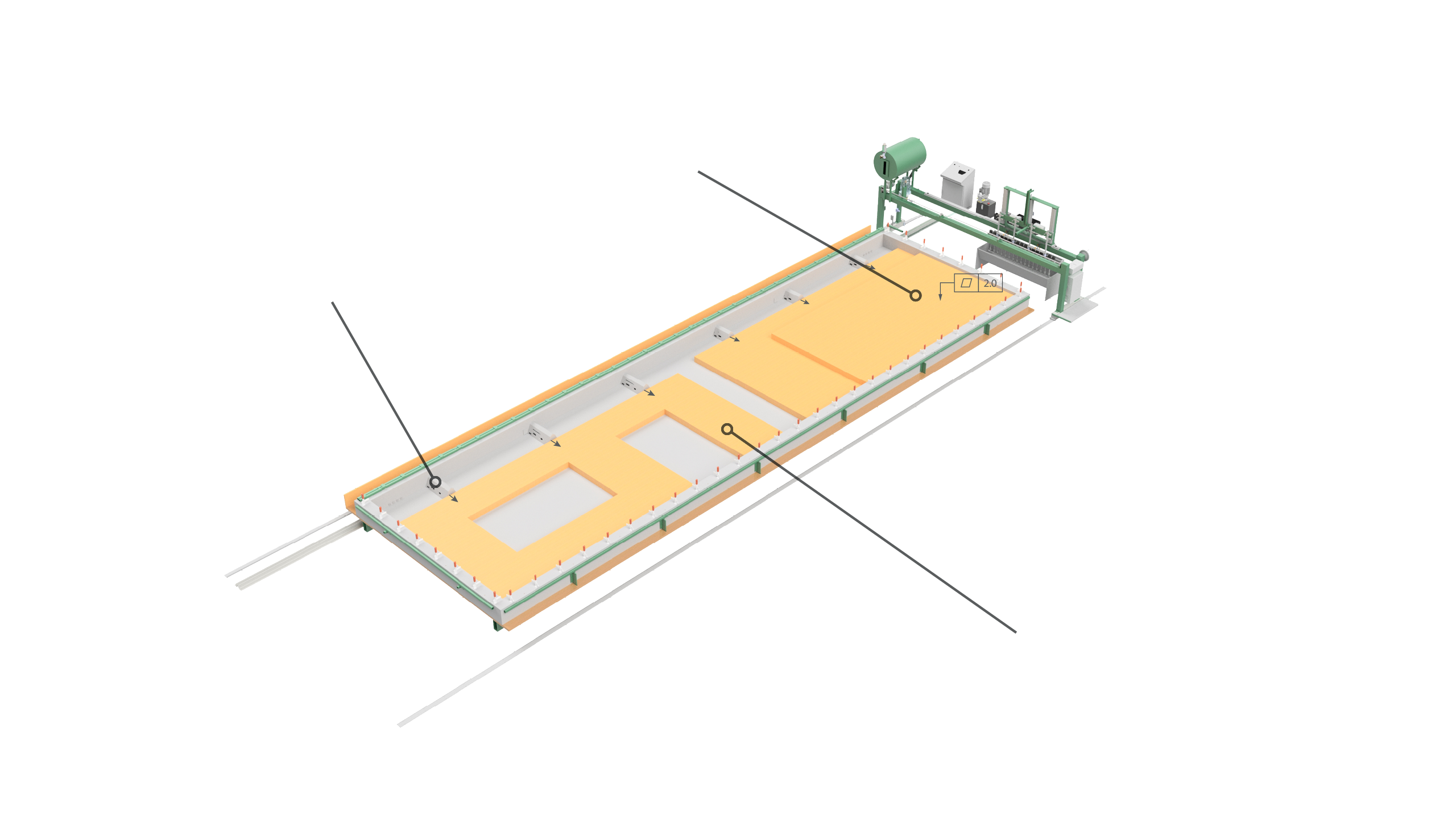

Vacuum Suction Plate

Infeed of all the Lateral Lamellas as one layer.

| Number of Operators: | 2 |

| Adhesive Open Time: | 20 – 30 min |

| Number of Pressing Cycles: | 5 / shift |

| Output 2 presses: | 8’000 m3 / year / shift |

| Output 3 presses: | 12’000 m3 / year / shift |

* indications for a 3.5×15 m press at 30% of the theoretical output

Videos aus der Produktion …

CLT with Lateral Lamella Conveyor

Extension Phase 2 – High efficiency thanks to the automated insertion of the lateral lamellas.

CLT with Vacuum Lifting System

Extension Phase 3 – Full Capacity of the production with preassembly tables and vacuum lifting solutions.

SIP Panel

Large-sized SIP Panel with integrated studs for floor cassettes: This is innovation!

User Cases

Latest News

Show All

Making your own CLT – is it worth it?

The leading timber journal mikado interviews Benjamin Fankhauser

First Hardwood CLT

BPS made of rosewood for MultiPly Pavilion in London on a vacuum press

Make your own CLT

BSP in Kundengrösse, gewünschter Qualität, Holzart und termingerecht herstell…

Low Investment and Maximal Flexibility

From small construction companies to the wood industry. What makes vacuum pre…