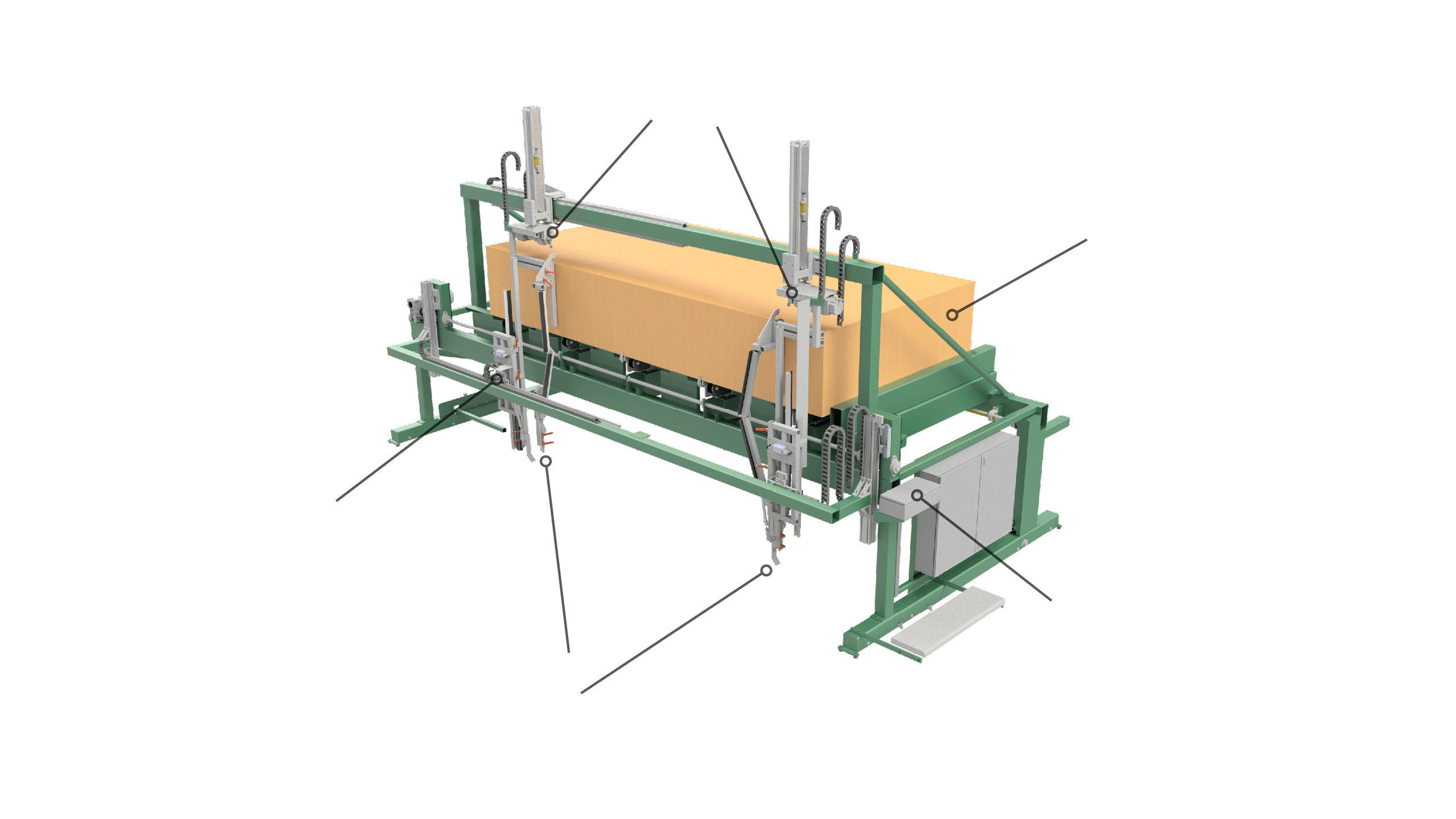

Lateral Lamella Conveyor Portal

Automated Destacking and Infeed of Lateral Lamellas

Play Product Video

Automation by

woodtec

Intelligent Combination of Sensors

and Manual Operation

Destacking Unit

Lamella Stack on Conveyor Belt

Infeed Unit

On-board Operator

Any Dimension

woodtec CLT Production: Extension Phase 2

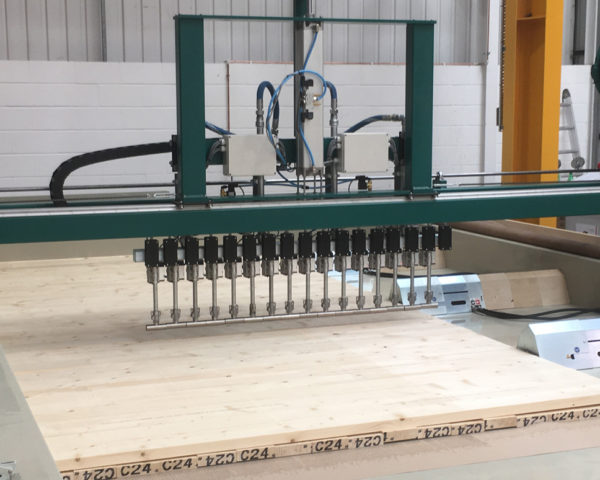

Destacking with single Operator

- Instead of 2 – 3 operators for manual infeed. Reduces the total number of operators for the complete process down to two.

Highly Compact

- All lateral lamellas for the panel are positionned on the portal. No need for additional prelaying tables.

Short Cycle Times

- With only 0.9 – 1.1 seconds per lamella the whole assembly time can be sped up. Use adhesives with shorter open times for more cycles.

Referenzen

Latest News

Show All

Making your own CLT – is it worth it?

The leading timber journal mikado interviews Benjamin Fankhauser

First Hardwood CLT

BPS made of rosewood for MultiPly Pavilion in London on a vacuum press

Make your own CLT

BSP in Kundengrösse, gewünschter Qualität, Holzart und termingerecht herstell…

Low Investment and Maximal Flexibility

From small construction companies to the wood industry. What makes vacuum pre…