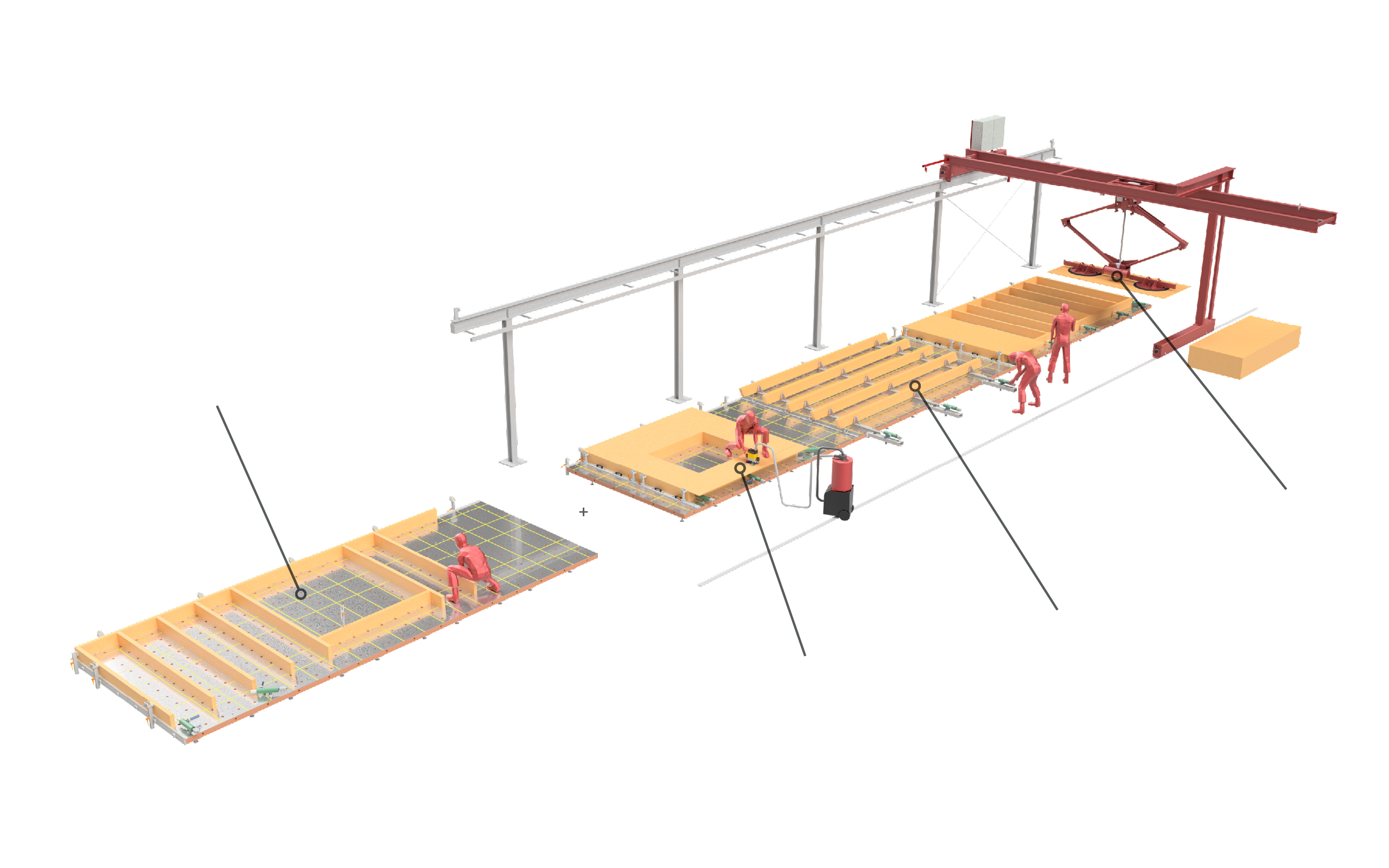

Timber Frame

Machines and Equipment for Prefab

Team Size 1

- A man works alone 20% faster than in a team. But he needs the right machines so that he can carry out all the production steps by himself.

Individual Work Stations

- One long assembly platform is subdivided in several work stations. According to the project’s needs. And in order to optimize the line’s output.

Optimized Production Steps

- Each step of the production can be optimized with the right equipment and accessories.

Human-Machine Interaction

- The craftsman should be able to maximize his productivity with suitable machines, systems and devices instead of being replaced by them.

Latest News

Show All

Prefab: Focus on Material Handling

The new production plant of Stuberholz AG does not score with fully automatic…

Making your own CLT – is it worth it?

The leading timber journal mikado interviews Benjamin Fankhauser

Stationary Workplaces Work Best

The Lehner GmbH from Heidenheim relies on stationary workplaces in their newl…

Added Storeys and Extensions

With increasing urbanization and the legislative measures against urban spraw…

Frame Prefab with Manpower

Industry 4.0 is not necessarily synonymous with automation and automation has…

Prefabricate Roofs

A new trend could emerge in the manufacture of roof trusses.

Modular Prefab

The trend towards individual solutions in timber construction and constructio…

Connecting with Adhesives

Fasteners do not always have to be used to manufacture wooden construction el…

Glued Box Girders – Completely Without Screws

Glued box girders for roofs and ceilings with a larger span